When it comes to documenting a project in 3D, you may find yourself comparing laser scanning and photogrammetry as possible solutions. Both technologies exist to achieve similar results, however depending on the scale of your project, desired level of accuracy and your budget one will typically be a better choice than the other. In some cases a combination of the two can produce the most desirable outcome.

So let’s break both technologies down and establish what applications each is best suited for.

Laser Scanning

This image taken from the FARO web site illustrates the basics of laser scanning. The scanner sends out a laser beam and when the beam hits a surface it bounces back to the scanner. The scanner records the distance the laser traveled before hitting an object and logs this information to a point in space.

On one side we have laser scanning, which has been around for decades. When it finally found its way into construction, architecture and engineering there was much excitement over the accuracy and speed of the new technology. Computers are finally advanced enough to handle the sheer volume of data the scanners produce usually in the form of point clouds.

Essentially, the laser scanner works by sending out hundreds of thousands of light pulses and measuring the distance between its location and objects the light pulses hit. For a more detailed explanation please read our article “The Basics of Laser Scanning.”

Photogrammetry

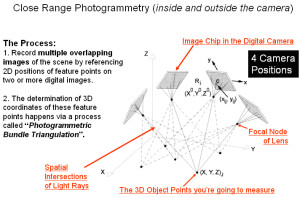

In its rudimentary form, photogrammetry has been around even longer than scanning. By simply knowing the location a picture was taken and the size of a reference object in the image, the position and size of objects can be calculated using triangulation. In 1999, David Lowe of the University of British Columbia developed a robust triangulation algorithm that launched photogrammetry into its modern day form, greatly increasing its accuracy, speed and applicability to various industries.

Digital photogrammetry today works by taking many images of a scene from different locations using standard digital cameras, even smartphones, and then processing them through programs to determine the exact location from which these photos were taken. When the positions of the camera are known, specialty software looks for common points in two or more photos to determine where objects exists in 3D space.

Comparison

Whenever there are multiple tools to get the job done we have to step back and weigh the differences. Accuracy, speed, costs, scale and the final use of the 3D data need to be considered when choosing between laser scanning and photogrammetry.

Below is a simple pro’s and con’s chart for both techniques followed by a discussion of favorable applications for each technique.

Laser ScanningPro’s

Con’s

|

PhotogrammetryPro’s

Con’s

|

Generally, laser scanning is your tool if you need a high level of accuracy over a large space. Photogrammetry is a better tool if you are documenting smaller spaces and are looking for less accuracy but more visual photo realism.

This is why photogrammetry is commonly used in the entertainment industry, such as for the creation of environments for games and movies. It is also being embraced by the archeological community because it allows for 3D documentation of individual objects with more realistic textures for a lower price than laser scanning.

Laser scanning on the other hand is more applicable to the architecture, engineering and construction (AEC) industries because of its level of accuracy over a large distance. AEC professionals are not as interested in photo realistic textures and much more sensitive to accuracy errors over distances which can quickly add up to inaccuracies of multiple feet in a large building using photogrammetry.

That said, there are some scenarios where a certain degree of accuracy can be acceptable, even in AEC application. For example, mining professionals are embracing photogrammetry for volume estimations as a more affordable alternative. In a recent case study, volume calculations were made of a 20,193 cubic yard pile of gravel using laser scanning and the newest photogrammetry tools. The photogrammetry calculation produced an error of 1.29 percent which was considered tolerable in this scenario.

Take Away

To summarize, when deciding between laser scanning and photogrammetry, the main questions you need to ask are:

- How much accuracy they really need?

- What the data will be used for?

- How easily can the data can be collected?

If you would like additional consultation, Lanmar is always available to you as a resource! Please send us an email or a call.

Additional Resources:

- Webinar comparing laser scanning and photogrammetry: http://novalearningnetwork.com/multistation-scanning-vs-photogrammetry/

- Application of laser scanning and photogrammetry to archeology: http://www.cescg.org/CESCG-2010/papers/Sarajevo-Radosevic-Goran.pdf

- Newest development in photogrammetry and application for mining: http://www.sparpointgroup.com/news/lidar/will-photogrammetry-make-laser-scanning-obsolete–

- Detailed paper comparing pro’s and con’s of photogrammetry and laser scanning: http://www.amerisurv.com/PDF/LaserScanningVsPhotogrammetry080108.pdf

Any news about the new scanner?

Excellent post! I should still 3D laser scanning in Serbia. The company I hired did his job professionally http://www.geourbgroup.com . I am very satisfied. All recommendations.

3D terrestrial laser scanning provides better and more versatile geodetic measurement solutions. The laser scanning technique enables remote data recording, which is particularly useful in inaccessible or inaccessible areas as well as areas with a large number of details. and i decided to hire Geourb Group, https://www.geourbgroup.com ,for 3d scanning of one of inaccessabile areas that i own in Belgrade Serbia.they`ve done great job.

Hi, I am an engineer at a leading AOI manufacturer, we create 3D images of circuit boards based on shadow moire based systems, there are some competitors who are making laser based systems, i have noticed that all big contract manufacturer companies are usually going with vision based systems instead of laser scanners, though laser scanner offer high height clearance as well as the speed. Can you tell me what could be the major reason behind this? The price is similar as well. I have heard that laser beam does get wider in a few years affecting the accuracy with which they read the height an djust like X ray based system, their source needs to be changed more often??

Hi Abhinav,

I work at an imaging company and had some questions regarding AOI for PCBs. Could you get in contact with me to discuss somet of the applications of photogrammetry in the field? Thanks in advance.

Excellent article. I was worrying about “only” budgeting for photogrammetry, as opposed to laser-scanning on a movie-project with a few CGI-Aided shots. But I can see now that it is pretty obvious we won’t be needing that level of accuracy at all. Thanks!